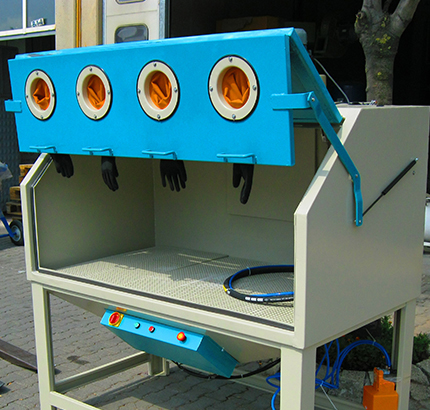

SV LINE VACUUM MANUAL SANDBLASTING CABINETS

SV LINE

FEATURES

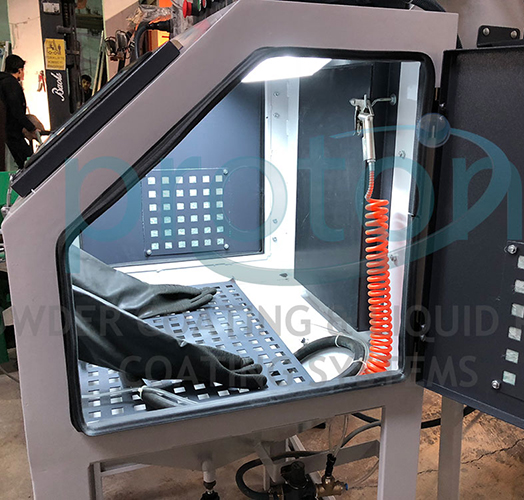

A blast cabinet is an effective way to clean, deburr, finish and prep a wide range of materials. No matter which type of media you’re using (aluminum oxide, glass beads, silicon carbide, plastic beads, or organic materials, etc.), Blast cabinets designed for continuous blasting will undoubtedly increase your production and lower your costs by replacing those manual, labor intensive operations like sanding, chemical cleaning, acid etching, wire brushing, and deburring.

Here at Elboy, we have a wide range of blast cabinets for your specific application, including light blast booths in various sizes, heavy pressure shot blast booths, wet blast booths and more.

CHOOSE A CABINET THAT SUITS YOUR BLASTING

Many of our customers approach us looking for blast equipment and abrasive media that suits their current cabinets and blasting setups. We encourage you to step back and determine if your blast cabinets are properly suited to the type of blasting you do. Consider several factors:

- Space: You need a blast cabinet with enough interior space to comfortably place the items you are blasting and be able to turn them to reach all surfaces.

- Lighting: Adequate lighting is critical for the best blast result and to obtain the right finish and level of cleanliness.

- Filtration: A powerful air filtration system helps keep the air clean so you can see what you are doing while working in your blast cabinet.

- Versatility: If you treat multiple types of materials, products and goods, make sure your cabinet can adapt to increase your versatility.

It doesn’t matter if you’re looking at installing an industrial blast cabinet for the first time or planning to upgrade an existing unit that no longer functions properly. Our Elboy team can help you choose the right equipment. We have the experience and knowledge to guide you according to the types of abrasive blasting you do and make sure that the blast cabinet you buy offers you flexibility, performance and value.

TOP-QUALITY BLAST CABINETS

As a market leader in industrial abrasive blasting and sandblasting, grit and media blast cabinets, our team is proud of our reputation. We have earned this reputation thanks to our focus on customer service as well as choosing to carry only top-quality blast cabinets and equipment. Our proven suppliers understand the pressures you have and build their equipment to last. Our quality media blast cabinets are easy to service and are built from quality materials so you experience less downtime.

When you contact us for a quote, we will ask you a few questions to make sure we are pointing you to the right blast cabinet purchase. Fill in our online contact form with information about:

- Direct Pressure for heavy production applications or bottom feed cabinet for lighter jobs?

- Do you have enough air?

- Your current compressed air power?

- Do you have information about proper nozzle sizing based on the required spray pattern and air fit?

- The nature of the objects you blast - is it metallic? non metal? coated?

- Overall size and shape of your pieces to determine the size of cabinet you need

- The types of abrasive blast media you will use

- What are your special requests for air filtration, rubber coatings (for harsh environments) or lighting?

CONTACT ELBOY FOR BLAST CABINETS AND MORE!

With this information, we can suggest the perfect blast cabinet for your application and help guarantee your satisfaction. Our goal is to provide you with all of the reliable, affordable and versatile blast equipment you need, so browse our catalog and contact us with your questions today.

CHECK OUT THE TECHNICAL INFORMATION TAB FOR OUR STANDARD MODELS.

S-V-900 |

S-V-1000 |

|||

| Sandblasting Cabinet Technical Specifications | Sandblasting Cabinet Technical Specifications | |||

| Air Consumption: 300-1000 lt / min | Air Consumption: 300-1000 lt / min | |||

| Working Pressure: 2-12 Bar | Working Pressure: 2-12 Bar | |||

| Abrasive Type: Glass Sphere (Glass sand), Aluminum oxide etc. | Abrasive Type: Glass Sphere (Glass sand), Aluminum oxide etc. | |||

| WORKING SPACE (mm ) | 900 X 700 X 720 | WORKING SPACE (mm ) | 1000 X 800 X 750 | |

| EXTERNAL DIMENSIONS (mm) | 950 X 1150 X 2000 | EXTERNAL DIMENSIONS (mm) | 1100 X 1250 X 2000 | |

| DOOR DIMENSIONS ( a x h mm ) | 580 X 590 | DOOR DIMENSIONS ( a x h mm ) | 670 X 630 | |

| FILTER TYPE AND QUANTITY | CARTRIDGE FILTER – 1 PIECE | FILTER TYPE AND QUANTITY | CARTRIDGE FILTER – 1 PIECE | |

| AIR CONSUMPTION ( m3 /min ) | 1 m3 / min ( 1000 lt/min ) | AIR CONSUMPTION ( m3 /dk ) | 1 m3 / min ( 1000 lt/min ) | |

| ELECTRICTY | 380 W | ELECTRICTY | 380 W | |

| TURNTABLE DIAMETER | 420 mm. | |||

| TURNTABLE WEIGHT CAPACITY | 350 kg | |||

| LOADING TROLLEY | Exist | |||

S-V-1300 |

S-V-1800 |

|||

| Sandblasting Cabinet Technical Specifications | Sandblasting Cabinet Technical Specifications | |||

| Air Consumption: 300-1000 lt / min | Air Consumption: 300-1000 lt / min | |||

| Working Pressure: 2-12 Bar | Working Pressure: 2-12 Bar | |||

| Abrasive Type: Glass Sphere (Glass sand), Aluminum oxide etc. | Abrasive Type: Glass Sphere (Glass sand), Aluminum oxide etc. | |||

| WORKING SPACE (mm ) | 1300 X 1000 X 1000 | WORKING SPACE (mm ) | 1800 X 1000 X 1000 | |

| EXTERNAL DIMENSIONS (mm) | 1400 X 1450 X 2100 | EXTERNAL DIMENSIONS (mm) | 1900 X 1450 X 2100 | |

| DOOR DIMENSIONS ( a x h mm ) | 860 X 780 | DOOR DIMENSIONS ( a x h mm ) | 860 X 780 | |

| FILTER TYPE AND QUANTITY | CARTRIDGE FILTER – 2 PIECES | FILTER TYPE AND QUANTITY | CARTRIDGE FILTER – 2 PIECES | |

| AIR CONSUMPTION ( m3 /dk ) | 1 m3 / min ( 1000 lt/min ) | AIR CONSUMPTION ( m3 /dk ) | 1 m3 / min ( 1000 lt/min ) | |

| ELECTRICTY | 380 W | ELECTRICTY | 380 W | |

| TURNET DIAMETER | 420 mm. | TURNET DIAMETER | 420 mm. | |

| TURNET WEIGHT CAPACITY | 350 kg | TURNET WEIGHT CAPACITY | 350 kg | |

| LOADING TROLLEY | Exist | LOADING TROLLEY | Exist | |

HI-PRESSURED CABINETS |

||||

| Sandblasting Cabinet Technical Specifications | ||||

| Air Consumption: 3000-4000 lt / min | ||||

| Working Pressure: 4-6 Bar | ||||

| Abrasive Type: Glass Sphere (Glass sand), Aluminum oxide,Steel Musket, Steel Grit etc etc. | ||||

S-V-P-1000 |

S-V-P-1300 |

|||

| WORKING SPACE (mm ) | 1000 X 800 X 750 | WORKING SPACE (mm ) | 1300 X 1000 X 1000 | |

| EXTERNAL DIMENSIONS (mm) | 1100 X 1250 X 2700 | EXTERNAL DIMENSIONS (mm) | 1400 X 1450 X 2800 | |

| DOOR DIMENSIONS ( a x h mm ) | 670 X 630 | DOOR DIMENSIONS ( a x h mm ) | 860 X 780 | |

| FILTER TYPE AND QUANTITY | CARTRIDGE FILTER – 1 PIECE | FILTER TYPE AND QUANTITY | CARTRIDGE FILTER – 2 PIECES | |

| AIR CONSUMPTION ( m3 /min ) | 3 – 4 m3 / min | AIR CONSUMPTION ( m3 /min ) | 3 – 4 m3 / min | |

| ELECTRICTY | 380 W | ELECTRICTY | 380 W | |

| TURNET DIAMETER | 420 mm. | TURNET DIAMETER | 420 mm. | |

| TURNET WEIGHT CAPACITY | 350 kg | TURNET WEIGHT CAPACITY | 350 kg | |

| LOADING TROLLEY | Optional | LOADING TROLLEY | Optional | |