ABRESIVE VACUUM RECOVERY UNITS

PROTON P-V LINE

PROTON equipment offers the right solution to recovering and conveying of blast medias, powders, plastic pellets, grains, sands, aggregates and other bulk metarials in both cleanup and material transfer functions.

The main type of industry using our equipments are blast cleaning companies, shipyards, tank cleaning companies, metallurgical plants and steel mills, foundries, power plants, cement industries, chemical industries etc..

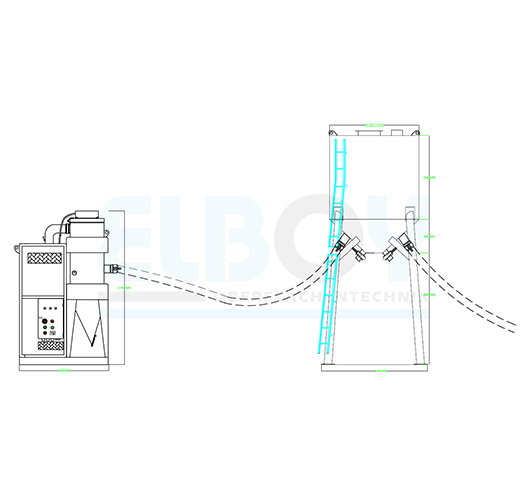

The dust in the air is collected by Vacuum Cleaner and the grit in the Stock Silo by its seperator.

Especially in inaccesable or enclosed areas such as storage tanks, box girder constructions, tank internals at shipyards etc., the equipment offers great savings in time and manpower.

A PROTON Vacuum system cuts costs by reducing cleanup time and reclaiming valuable materials.

This versatile vacuum system can be used to pick up any material that will flow through a hose.

With its long reach and powerful suction, PROTON cleans out tanks, pipes. There are 2 types of stock silos, Cylindirical and Square having 2 floors.

Technical Specifications for standard machines:

VC Unit’s cost-cutting power has been proven hundreds of times.In fact, most VC units pay for themselves in less than 3 months through reduced labour costs and reclaimed materials.

Units are available with capacities up to twelve tons per hour, conveying distances up to 330’’(100m),and motors from 7,5kW-90kW(3,98m³/min-72m³/min).

Performance data for air (p₁=1,0 bar, t₁=20 °C, ρ=1,2 kg/m³)

| PROTON SERIES | VC 7,5 | VC 18,5 | VC 30 | VC 37 | VC 45 | VC 55 | VC 75 | VC 90 | All sets include the following equipment. - Suction Hose (rubber-wired) - Suction Hose for connection between Vacuum Unit and Hopper - Suction Nozzle - Cam-lock and clamp Connections - Cartridge Filter(spare) - Oil for Blower(spare) - Manometer(spare) - Phase Protection Relay - all necessary fasteners |

| Recovery Rate | 0,5-1 | 0,8-2 | 1,2-4 | 1,5-5 | 2-7 | 3-8 | 5-12 | 6-15 | |

| (tons/per hour) | |||||||||

| Electric Motor | 7,5kW | 18,5kW | 30kW | 37kW | 45kW | 55kW | 75kW | 90kW | |

| NG (rpm) | 3740 | 3660 | 3680 | 3680 | 3300 | 2965 | 3710 | 3710 | |

| NM (rpm) | 2910 | 2930 | 2945 | 2945 | 2955 | 2965 | 2970 | 2975 | |

| Vacuum Producer | GM 4S | GM 15L | GM 25S | GM 25S/30L | GM 30L/35S | GM 50L | GM 50L/60S | GM 60S/80L | |

| (AERZEN Blower) | |||||||||

| Q1(m³/min) | 3,98 | 12,6 | 18,2 | 25,7 | 33,8 | 42,7 | 54,6 | 72 | |

| t² (°C) | 74 | 70 | 67 | 67 | 66 | 66 | 65 | 67 | |

| Suction Distance | 8mt | 15mt | 20mt | 25mt | 30mt | 40mt | 50mt | 60mt | |

| (Recommended) | |||||||||

| Max. Suct. Distance | 13mt | 22mt | 32mt | 36mt | 45mt | 60mt | 80mt | 100mt | |

| Cartridge Filter Qua | 1pcs | 2pcs | 2pcs | 2pcs | 2pcs | 2pcs | 4pcs | 4pcs | |

| Filter Surface(m²) | 2 | 8 | 12 | 12 | 18 | 22 | 32 | 42 | |

| Start-Stop Method | star-delta | star-delta | star-delta | star-delta | star-delta | star-delta | star-delta | star-delta | |

| Max. Noise Level(dB) | 75 | 75 | 80 | 85 | 85 | 85 | 90 | 90 | |

| Cyclone Seperator& Hopper | 0,8 m3 | 1 m3 | 1,5 m3 | 1,5 m3 | 2,5 m3 | 4 m3 | 4 m3 | 5 m3 | |

| Electrical Supply | 380Volt-50Hz/440Volt-60Hz or 380Volt-60Hz | ||||||||