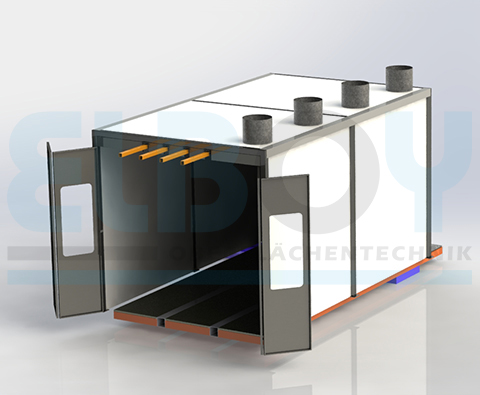

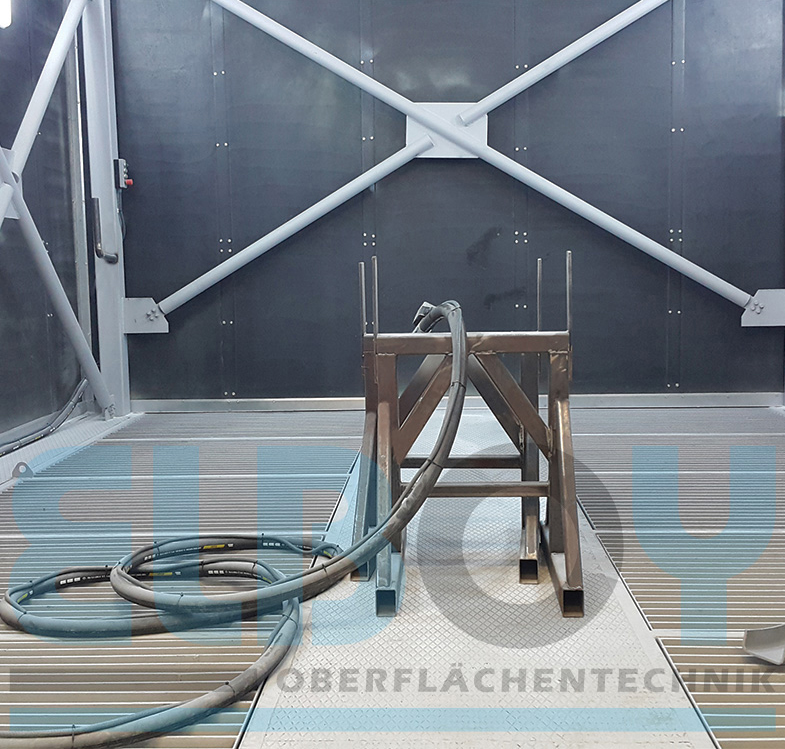

MANUEL SANDBLASTING BOOTH

SR-LINE

A blast room is a much larger version of a blast cabinet. Blast operators work inside the room to roughen, smooth, or clean surfaces of an item depending on the needs of the finished product. Blast rooms and blast facilities come in many sizes, some of which are big enough to accommodate very large or uniquely shaped objects like rail cars, commercial and military vehicles, construction equipment, and aircraft.

Each application may require the use of many different pieces of equipment, however, there are several key components that can be found in a typical blast room:

Main Booth

Sandblasting rooms are designed to prevent the abrasive inside from escaping and provide a clean working environment.

Sandblasting room walls are covered with special sandblasting rubber and the main construction is prevented from being damaged.

The blasting chamber can be placed on a steel frame with a ramp or directly on the factory floor. On the side of the cabin, there are emergency exit doors with protective windows. Dust collector, elevator, separator, vacuum machine, abrasive silos and sandblasting pots can be placed on the side or back of the cabin.

Blasting pot

A pressurized container filled with abrasive blasting media. Blasting pots can be different quantity and different capacities. The abrasive used in the cabin is refilled into the sandblasting pots with various recycling systems.

Click for detailed information about Sandblasting pots.

Dust collection system

Which filters the air in the room and prevents particulate matter from escaping. The dust collectors can be different quantity and different capacities according to blasting room dimensions.

Click for detailed information about Dust Collection systems.

Reclaimation System

A material recycling or media reclaimation system to collect abrasive blasting media so it can be used again; these can be automated mechanical or pneumatic systems installed in the floor of the blast room, or the blast media can be collected manually by sweeping or shoveling the material back into the blast pot.

Click for detailed information about recycling systems.

Fresh Air Feeding

Fresh air is fed into the cabin with fans or free suction chimneys depending on the size of the cabin.

Additional equipment can be added for convenience and improved usability, such as overhead cranes and trolleys for maneuvering the workpiece, wall-mounted units with multiple axes that allow the operator to reach all sides of the workpiece, and sound-dampening materials used to reduce noise levels.

Sandblasting rooms are designed in accordance with European standards and safety norms.