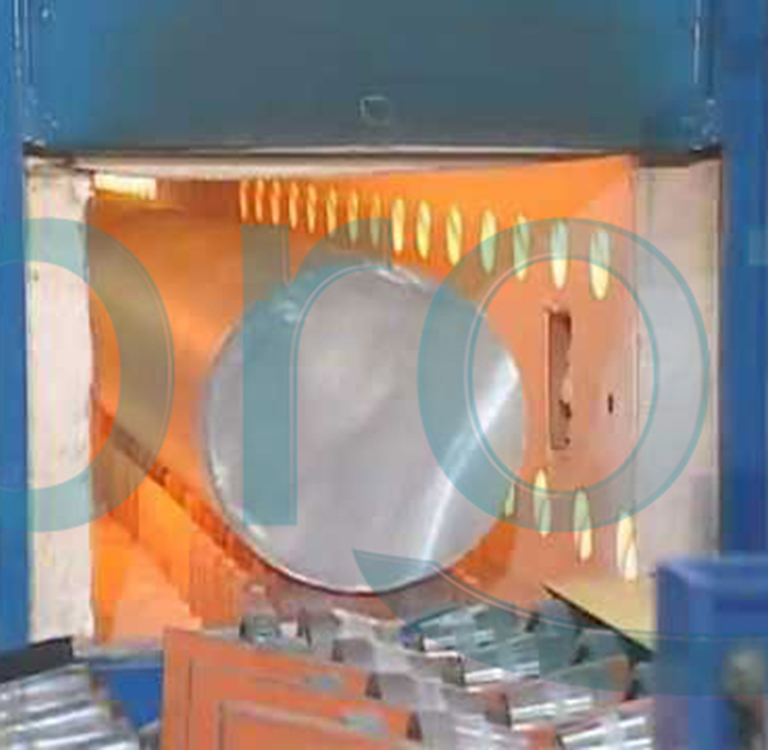

Billet Heating Furnaces

Aluminum Billet / Billet Heating Furnaces are used in the pre-heating process before extrusion.

These furnaces are directly gas heated and have premixed jet type nozzle burners controlled by PLC.

Thanks to the special arrangement of the burners, it is ensured that the billets are heated in a conical manner with low gas consumption in a short time.

Temperature measurement is made at measurement ranges determined by surface thermocouples that directly contact the billet / billet surface and can move back and forth.

After the process, a temperature distribution better than ± 10° C is achieved on the material surface.

By reusing the flue gases formed in the pre-heating zone, the gas consumption is reduced and the heating efficiency is increased. Low thermal mass insulation materials and easily replaceable refractory blocks are used in furnace insulation. By using insulation materials with low heat retention capacity, the problem of melting of the materials in the furnace in case of interruption is prevented. The furnace transfer system has a roller conveyor structure and is designed to work in harmony with hot billet cutting machines.